The Perfect Armor Improved: Water Hardened

Leather

Some years ago, I wrote an article on how to make hardened

leather armor, using beeswax. Since then, I have concluded that although

the method I described works reasonably well for SCA purposes--I have fought

in my wax hardened klibanion for a good many years now--it is quite unlikely

that it is the method used in period for armor.

I reached that conclusion for three reasons:

1. Beeswax is a lubricant. Furthermore, stiffening the

leather makes it easier to cut, just as it is easier to slice meat if it

is half frozen. So although wax hardened leather provides protection against

the sort of blunt weapons we fight with, it would be of very limited usefulness

against sharp swords, arrows, and the like.

2. Although I have found no period descriptions of the

process for hardening leather, the period term for hardened leather is "cuirboulli,"

which translates as "boiled (or cooked) leather." That is not

the natural way of describing the wax hardening process.

3. I have found an entirely different way of hardening

leather which does fit the term and which produces armor that is much better

protection against real weapons. This article describes that process. As

it happens, in addition to being a better guess at what was done in period,

it is also a somewhat better technology for making SCA armor.

How to Water Harden Leather

Take a piece of vegetable tanned leather. Immerse it in

water long enough to get it soaked--ten minutes will do. Heat a pot of water

to 180°. Immerse the leather in the hot water. Watch it.

In about a minute, the leather will begin to darken, go

limp, and curl up. If you pull it out at that point, it will have shrunk

a little, thickened a little, and be stretchy, like a thick sheet of rubber;

at this point it can be stretched and formed. In a minute or two the stretchiness

will go away, but the leather will still be flexible. Over the course of

the next few hours it will become increasingly stiff. You will end up with

a piece a little thicker and a little harder than what you started with.

The longer you leave the leather in the hot water after

the process has started, the more it shrinks, the more it darkens, the thicker

it gets--and the harder the final piece will be. A sufficiently long immersion

gives you something that feels like wood. Unfortunately, when the piece

gets harder and stiffer it also gets more brittle. If I were making lamellar

armor to defend myself against real weapons, I would use a long immersion--and

plan on replacing a few cracked lamellae after each fight. For SCA purposes,

I normally leave the leather in the hot water for about thirty seconds after

the process starts. This gives me, very roughly, shrinkage to about 7/8

of the original dimensions, an increase in thickness of about 25%, and a

piece that is hard but not totally inflexible.

The process is very sensitive to the temperature of the

water, so you will want an accurate thermometer. The timing and the result

also depend to some degree on the particular piece of leather. Instead of

trying to work entirely by the clock, experiment with pieces of scrap until

you have a reasonably good idea of how the leather looks at various stages

in the process and how it comes out when finished, then judge the progress

of your piece in part by time and in part by appearance.

You can also harden leather in in boiling water--considerably

faster. In my experience, about a twenty second boil gives shrinkage to

7/8ths, about a forty second gives you a shrinkage to 2/3 and roughly doubles

the thickness. That has the advantage of not requiring a thermometer.

It has two disadvantages. First, the faster process is

harder to control precisely. Second, the hotter water produces a less uniform

hardening--you tend to get pieces where the surface is harder and more brittle

than the interior, eventually producing surface cracks. I therefore prefer

the lower temperature process. I have not done any extensive experimentation

on what happens at intermediate temperatures.

Easy Projects

Making flat pieces such as lamellae or scales is easy.

Because it is hard to predict the exact amount of shrinkage, you may want

to first to water harden the whole piece of leather, then flatten it under

a cutting board or something similar for a few minutes, then cut out your

lamellae with a utility knife and add holes with a leather punch; at this

stage in the process the leather can still be cut fairly easily.

If I want my lamellae slightly curved in the horizontal

direction, to provide a little additional stiffness and to better fit my

body, I take a cooking pot with a diameter of a foot or more, line up the

lamellae around it while they are still flexible, tie them on with a strip

of rag, and let them dry that way.

Making a vambrace, a rerebrace, or any other piece that

is curved but not stretched--any shape you could make from a sheet of paper--is

equally easy. Cut the piece of leather a little bigger than you think you

need (remembering to allow for shrinkage), harden it. Wrap a towel around

your forearm to protect it from heat and provide extra thickness to allow

for padding (or wear your gambeson, if it covers your arm). Tie the piece

of leather around your arm with strips of cloth (string will leave marks

on the leather). Leave it there for fifteen minutes or so. Untie it and

take it off, being careful to keep the shape--at this point the leather

is still fairly flexible. Trim off any surplus. Leave it somewhere to dry.

Instant vambrace.

Making a vambrace, a rerebrace, or any other piece that

is curved but not stretched--any shape you could make from a sheet of paper--is

equally easy. Cut the piece of leather a little bigger than you think you

need (remembering to allow for shrinkage), harden it. Wrap a towel around

your forearm to protect it from heat and provide extra thickness to allow

for padding (or wear your gambeson, if it covers your arm). Tie the piece

of leather around your arm with strips of cloth (string will leave marks

on the leather). Leave it there for fifteen minutes or so. Untie it and

take it off, being careful to keep the shape--at this point the leather

is still fairly flexible. Trim off any surplus. Leave it somewhere to dry.

Instant vambrace.

Harder Projects

One advantage of water hardening is that when the piece

comes out of the water it is stretchy--more so than leather that has been

soaked for a much longer time in cold water, as described in my earlier

article. This makes it possible to form pieces. You must work quickly, since

the stretchiness goes away in a minute or two.

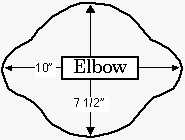

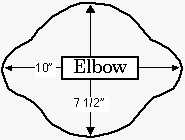

Elbow cops are easy. Start with a roughly oval shape, about

10" by 7.5", as shown in the figure. Find two bowls, diameter

about 6.5", that will nest together. When the piece comes out of the

hot water, put it into one of the bowls, forcing it down with your fingers

to stretch the leather into the bowl, then put in the other bowl, so that

the leather is being stretched between the two.

Finally, take out the inside bowl and make sure that the

leather is fitting into the other with no folds, crinkles, etc.--if necessary

smooth those out with your fingers. Let the leather dry. Sew or rivet on

straps and you have an elbow cop. For a knee cop, do the same thing, making

the piece about 14" x 7.5" and using about 7.5" diameter

bowls. Details will vary according to the size of your elbow and knee and

how thick your padding is going to be.

A bazuband--the Islamic forearm and elbow piece described

in the previous article and shown here--is a more complicated shape. There

are four ways to try to make it.

1. Use your arm, wrapped in a towel, as the mold. This

will probably work better with two people, giving you three hands to stretch

leather. I have not yet tried doing the initial stretching that way, although

I usually put the piece over my arm for the final adjustments.

2. A positive form. Get something roughly the shape of

the inside of the bazuband. A steel bazuband is ideal if you happen to have

one lying around, but lots of other things will do. For a less precisely

designed form, but one somewhat easier to obtain, use a wine bottle with

relatively steep shoulders.

With a positive form, you take the leather out of the hot

water and stretch it over the form. I find that it helps to tie the wrist

end of the leather around the form with strips of cloth, then do the stretching

at the elbow end, which is where it is most needed. then tie that down to

the form with strips of cloth. This is like making an elbow cop with only

one bowl, by stretching the leather over the bowl--but harder. You may find

it useful to do some preliminary stretching over a rounded corner of the

kitchen table, or something similar.

3. A negative form. Get something that is roughly the shape

of the outside of the bazuband and stretch the leather into it--like forming

your elbow cop in the inside of a bowl.

4. Nested forms. This is the best way--once you have

the forms. I've done it using a pair of steel bazubands. They don't have

to be steel--once you have made a cuirboulli bazuband you are happy with,

you can use it as your negative form for the next one, nested onto whatever

form you used to make it.

4. Nested forms. This is the best way--once you have

the forms. I've done it using a pair of steel bazubands. They don't have

to be steel--once you have made a cuirboulli bazuband you are happy with,

you can use it as your negative form for the next one, nested onto whatever

form you used to make it.

Alternatively, you could make both positive and negative

forms out of wood--by the next version of this article, I may have finished

that project, using lengths of 2x4 sandwiched together and pegged. In theory,

you end up with forms that can be made narrower, for thin people's arms,

by removing the central piece, or wider, for big people's legs, by adding

another piece.

Dimensions

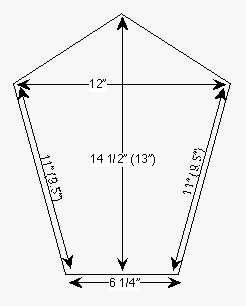

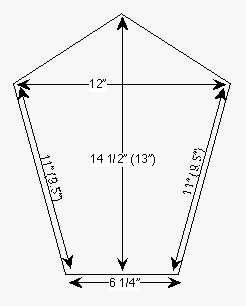

The figure on the next page shows a piece of leather intended

for a bazuband and top and bottom views of the completed piece; numbers

in parentheses were measured after shrinkage. My wrist circumference is

7.5", and my arm is 9" from the wrist to the tip of the elbow,

8" from the wrist to the inside of the bend of the elbow. You can experiment

with different starting shapes and forms to make different sorts of bazubands.

After doing your best you can to stretch the leather over

or into your form, you may discover that your best was not good enough--the

edge of the leather at the elbow won't fit against the form without wrinkling.

Simple Fixes

There are two possible solutions. One is selective shrinkage.

Put the edge of the elbow end back into the hot water for another minute

or two, until it starts to get darker and shrink. With luck, you can tighten

the wrinkles away. A simpler solution, shown to the left, is to pinch the

tip of the elbow end, giving you one elegant fold instead of several inelegant

wrinkles. Hold the pinch closed with a clamp while the leather dries and

stiffens.

There are two possible solutions. One is selective shrinkage.

Put the edge of the elbow end back into the hot water for another minute

or two, until it starts to get darker and shrink. With luck, you can tighten

the wrinkles away. A simpler solution, shown to the left, is to pinch the

tip of the elbow end, giving you one elegant fold instead of several inelegant

wrinkles. Hold the pinch closed with a clamp while the leather dries and

stiffens.

After discovering how simple the technology is it may occur

to you, if you are a parent, that cuirboulli armor is just what your five

year old would like for Christmas--and considerably less expensive than

the latest Playmobile castle. The idea is not new. The pictures below show

two father/son pairs of bazubands--one Indian, possibly 18th century, and

one a little more recent.

Doing without Bicycle Tires and Heater Hose

A simpler stretched leather project is shield edging. Start

with a strip about 3 inches wide and long enough to go around your shield

after allowing for shrinkage--or several strips that add up to enough length

if you prefer. When the leather goes limp, pull it out of the water and

stretch it tightly around the shield; it will form itself to the shield

edge in a fashion wonderous to behold. To completely eliminate non-period

materials from your shield, use many layers of scrap wool to provide padding

between the wood and the leather.

Further Details

For SCA fighting, you should probably start with at least

8 ounce leather, which the hardening process will thicken to about 10 ounce.

12-14 ounce is better--but harder to stretch over forms. In general, you

will want thicker leather over vulnerable points such as knees and elbows--which

means either starting with thicker leather or leaving your leather in the

hot water longer to get more shrinkage.

Sometimes something will go wrong; you pull the piece of

leather intended for a bazuband out of the water only to discover that it

has shrunk too much to fit your form, or that a thin section you didn't

notice has shriveled up, ruining the piece. All is not lost. Flatten the

piece out and cut it into lamellae. Enough mistakes and you have a free

klibanian.

One minor problem with the process is that the leather

gradually turns the water you are using brown. For a simple project, such

as making lamellae, this may be tolerable; you can stir the piece of leather

to the top of the pot every ten seconds or so to check its condition. For

something more complicated, such as a bazuband or greaves, you may want

to heat fresh water for each piece--which is a nuisance but makes it easier

to see what you are doing.

For the Future

I am fairly sure that water hardened cuirboulli, starting

with 14 oz leather, would be adequate for gauntlets but I have not yet made

any. Starting with even thicker leather I could probably make a workable

helmet--but I doubt I could talk the marshalls into letting me use it. I

do, however, plan to fight at Pennsic this year wearing my brand new cuirboulli

cup.

Cuirboulli can also serve a variety of more peaceful purposes.

Think of it as a medieval plastic-literally true, if you take "plastic"

in its general sense and consider the condition of the leather immediately

after it comes out of the water.

Making a vambrace, a rerebrace, or any other piece that

is curved but not stretched--any shape you could make from a sheet of paper--is

equally easy. Cut the piece of leather a little bigger than you think you

need (remembering to allow for shrinkage), harden it. Wrap a towel around

your forearm to protect it from heat and provide extra thickness to allow

for padding (or wear your gambeson, if it covers your arm). Tie the piece

of leather around your arm with strips of cloth (string will leave marks

on the leather). Leave it there for fifteen minutes or so. Untie it and

take it off, being careful to keep the shape--at this point the leather

is still fairly flexible. Trim off any surplus. Leave it somewhere to dry.

Instant vambrace.

Making a vambrace, a rerebrace, or any other piece that

is curved but not stretched--any shape you could make from a sheet of paper--is

equally easy. Cut the piece of leather a little bigger than you think you

need (remembering to allow for shrinkage), harden it. Wrap a towel around

your forearm to protect it from heat and provide extra thickness to allow

for padding (or wear your gambeson, if it covers your arm). Tie the piece

of leather around your arm with strips of cloth (string will leave marks

on the leather). Leave it there for fifteen minutes or so. Untie it and

take it off, being careful to keep the shape--at this point the leather

is still fairly flexible. Trim off any surplus. Leave it somewhere to dry.

Instant vambrace.

4. Nested forms. This is the best way--once you have

the forms. I've done it using a pair of steel bazubands. They don't have

to be steel--once you have made a cuirboulli bazuband you are happy with,

you can use it as your negative form for the next one, nested onto whatever

form you used to make it.

4. Nested forms. This is the best way--once you have

the forms. I've done it using a pair of steel bazubands. They don't have

to be steel--once you have made a cuirboulli bazuband you are happy with,

you can use it as your negative form for the next one, nested onto whatever

form you used to make it.

There are two possible solutions. One is selective shrinkage.

Put the edge of the elbow end back into the hot water for another minute

or two, until it starts to get darker and shrink. With luck, you can tighten

the wrinkles away. A simpler solution, shown to the left, is to pinch the

tip of the elbow end, giving you one elegant fold instead of several inelegant

wrinkles. Hold the pinch closed with a clamp while the leather dries and

stiffens.

There are two possible solutions. One is selective shrinkage.

Put the edge of the elbow end back into the hot water for another minute

or two, until it starts to get darker and shrink. With luck, you can tighten

the wrinkles away. A simpler solution, shown to the left, is to pinch the

tip of the elbow end, giving you one elegant fold instead of several inelegant

wrinkles. Hold the pinch closed with a clamp while the leather dries and

stiffens.